Wilwood 160-5865 Ulltralite 32 Vane Rotor Drilled

Wilwood

Wilwood On demand

Wilwood 160-5865 Ulltralite 32 Vane Rotor Drilled

Ulltralite 32 Vane Rotor Drilled

When it comes to rotors, racers are constantly searching for the ultimate balance between the lowest weight and the ability to effectively manage heat. Decreased rotating weight in the drive line provides quicker deceleration under braking and quicker acceleration out of the corners. Lower weight also benefits handling with improved spring and shock control over the unsprung suspension mass. Wilwood's ULD-32 drilled iron rotors provides effective lightweight options for sprints, late models, modifieds, and other competition applications that race in low to medium temperature ranges.

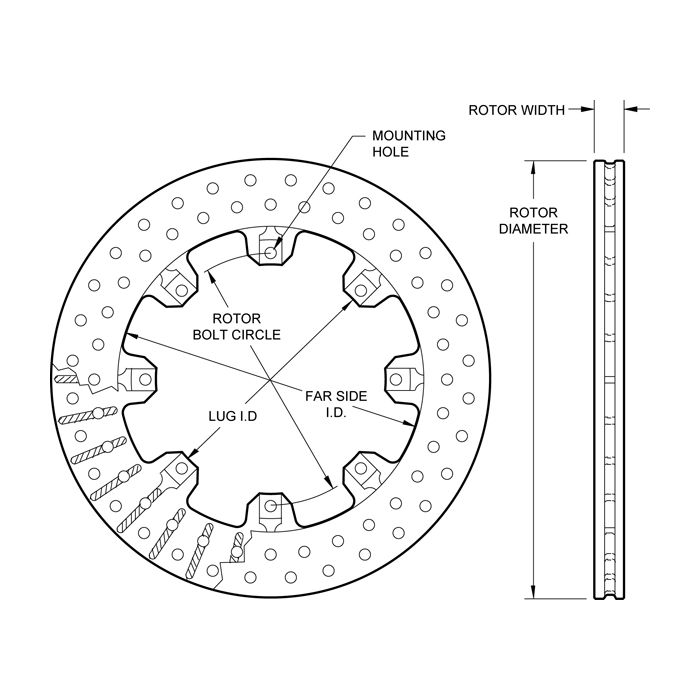

| Rotor Dimensions | |

|---|---|

| Width (in) | 0.81 |

| Diameter (in) | 12.19 |

| Mount Side | Non_Direct |

| Rotor Design | |

| Material | Iron |

| Vane Count | 32 V |

| Weight(Lbs) | 8.00 |

| Rotor Style & Finish | |

| Type | ULD |

| Style | Race Drilled |

| Surface Finish | Plain |

| Rotor Upgrades | |

| Bedded | No |

| Balanced | No |

Additional Rotor Dimensions

| Rotor Bolt Circle (in) | 8 x 7.00 |

| Rotor Mount Hole Size (in) | 0.326 |

| Lug ID / Registration (in) | 6.38 |

| Far Side Inside Diameter (in) | 8.56 |

Performance Characteristics

- Race Drilled Rotors are unsafe for street use.

- Suitable applications: Light to moderate Dirt Racing

- Can result in failure if misused.

Additional Notes

ULD-32 Series Drilled Straight Vane Vented Iron Rotors feature a two row, 64 hole pattern that alternates between and directly over each vane. Each hole is deeply chamfered to eliminate any stress points that could result in premature cracking at the drill holes. The drilling process removes an average of one pound from each rotor. Rotating and unsprung rotor mass is reduced by as much as 12%.

Caution on drilled rotors: There is a common mis-perception that rotors are drilled to improve cooling. The reduced mass of a drilled rotor will dissipate its retained heat quicker, but it also builds up heat a much faster rate. The decision to use drilled rotors should be solely based on the merits of the lower rotating and unsprung weight, and Nt for improved cooling. It is Nt wise to use drilled rotors in sustained high heat on hard braking tracks unless the team budget affords a high frequency of rotor and brake pad replacement.

More Information

| Manufacturer |  Wilwood Wilwood |

|---|